Feb 21, 2025

In the manufacturing industry, CNC (Computer Numerical Control) machines have become essential tools for improving production efficiency, ensuring precision, and reducing labor costs. For B2B clients, selecting the right CNC equipment is a critical step in optimizing production processes. This article will focus on two popular types of CNC machines—Automatic CNC Bending Centers and CNC Punch Presses—to help you make an informed decision based on your business needs.

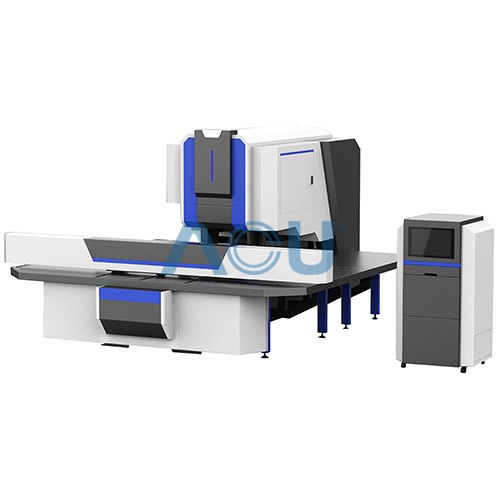

The Advantages of Automatic CNC Bending Centers

Automatic CNC bending centers are ideal for the metal fabrication industry, particularly for producing complex parts that require high-precision bending. These machines excel in automating repetitive tasks, significantly reducing manual intervention and boosting production efficiency. For instance, automatic CNC bending centers can quickly handle large volumes of metal sheet bending while maintaining consistent dimensions and angles for each product. Industries such as automotive and aerospace, which demand high precision and repeatability, greatly benefit from these advanced machines.

The Versatility of CNC Punch Presses

CNC punch presses are renowned for their versatility and efficiency. They can perform a variety of operations, including punching, cutting, and forming, by simply changing the tooling. This makes them an excellent choice for businesses that need to produce a wide range of products, such as electronic enclosures or architectural metal components. Compared to traditional mechanical punch presses, CNC punch presses offer higher precision and flexibility, making them suitable for customized production requirements.

Matching CNC Machines to Your Production Needs

When selecting a CNC machine, it’s crucial to evaluate your specific production requirements. If your business primarily involves bending and shaping metal sheets, an automatic CNC bending center may be the better option. On the other hand, if you need to handle diverse shapes and sizes, a CNC punch press might be more suitable. Additionally, factors such as production capacity, precision requirements, and budget should also be considered to ensure the chosen machine aligns with your business goals.

Enhancing Productivity Through Automation

Both automatic CNC bending centers and CNC punch presses leverage automation to enhance productivity. Automated CNC machines minimize human error, shorten production cycles, and reduce labor costs. For B2B clients looking to stay competitive, investing in automated CNC equipment is a strategic move toward achieving scalable and efficient production.

The Importance of Maintenance and Support

Beyond the machine’s performance, it’s essential to consider after-sales service and technical support when purchasing CNC equipment. Reputable suppliers offer comprehensive training, regular maintenance, and responsive technical assistance to ensure the machine operates smoothly over the long term. This is particularly important for minimizing downtime and maintaining consistent production output.

The Future: Smart CNC Machines

As Industry 4.0 continues to evolve, smart CNC machines are becoming a significant trend in the manufacturing sector. Future automatic CNC bending centers and CNC punch presses will integrate IoT (Internet of Things) technology, enabling remote monitoring and data analysis to further improve efficiency and product quality. For B2B clients, adopting smart CNC machines early can provide a competitive edge in an increasingly digitalized market.

Read More